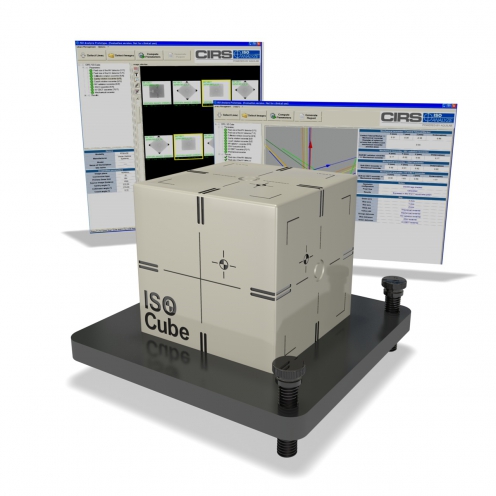

ISO Cube Daily QA Phantom Model 023

Economical * Accurate * Easy to Use

Target positioning through imaging guidance is critical for the accurate delivery of radiation treatment. Verifying that all of the imaging, localization and targeting systems are aligned with the true radiation isocenter is crucial. The CIRS ISO CubeTM provides a cost-effective, quick and accurate means of testing radiation isocenter coincidence with the isocenters of the image guidance systems.

The ISO Cube is designed specifically for daily system checks. LINAC lasers and light field can be “tuned” to the true radiation isocenter using the engraved markings on the exterior of the ISO Cube. The light field and radiation field alignment can be checked using built-in radiographic markers. More importantly, the isocenters of both the OBI and the EPID can be checked for true spatial alignment and coincidence with that of the treatment beam.

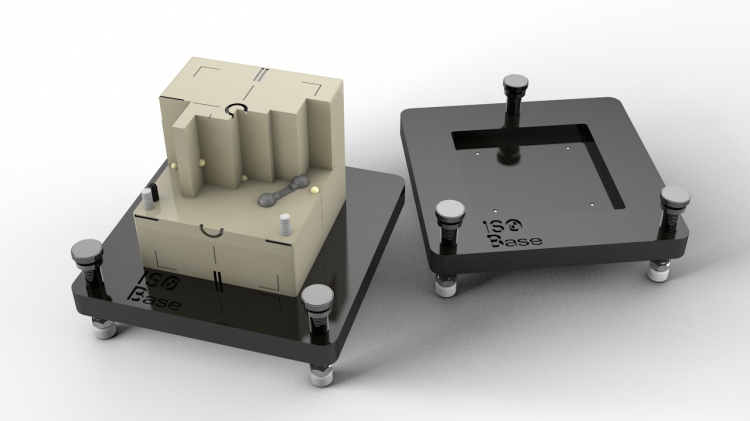

The ISO Cube contains a unique center point fiducial and an offset target. The offset target is used to ensure the table offset coordinates generated by kV/MV imaging are accurate by locating the target, moving the table the determined amounts and verifying that the offset target has been positioned at the isocenter. The center fiducial and off-set target measure 6.35 mm in diameter and are made of ceramic. The exterior is machined with concentric circle targets to allow user to objectively assess all setup errors, including rotations, and to easily align the phantom to the true radiation isocenter. ISO Cube is manufactured with machining tolerance of ± 0.02 mm. Target positioning accuracy is ± 0.1 mm.

An optional optical target frame adapter is available that mechanically registers any frameless SRS RF or optical tracking target array to the ISO Cube in a simple and repeatable manner. The users can mount the target array via adhesive or mechanical fasteners of their choosing.

There are two platforms available for use with ISO Cube. One is designed to register with couch indexing bars and provide indices for incremental adjustment of pitch, roll and yaw. The second platform provides leveling legs and embedded markers for kV/MV pixel size computation using Iso Analyze software.

Features:

- Fast and easy to use

- Unique fiducials produce sharp clear images in EPID, kV and CBCT imaging

- Offset fiducial to check accuracy of couch corrections

- Check- Laser alignment

– Light field size verification

– kV and MV imager coincidence

– CBCT process accuracy

– OBI accuracy

– Table height accuracy

– Radiation field/light field alignment

ISO Analyze™ Image Analysis Software integrates with the ISO Cube™ Daily QA Phantom and ISO Base™ Alignment Platform, enabling user-friendly quality control of the isocenter of a LINAC by analyzing DICOM images acquired with the EPID detector. Controls are run automatically, analyzing the image of the ISO Cube™ and quantifying a large number of evaluation parameters. It allows users to easily generate a report for each preceding control.

Ask about our ISO Cube™ Daily QA Package (023-05)